Unitree Unveils AI-Powered Factory System Where Robots Build Themselves

Unitree Robotics has demonstrated a groundbreaking embodied AI system capable of autonomously manufacturing and assembling its own robotic units within a factory environment. The revelation, backed by internal footage and corporate disclosures, marks a pivotal leap toward fully autonomous production in robotics.

Unitree Unveils AI-Powered Factory System Where Robots Build Themselves

In a paradigm-shifting development in industrial automation, Unitree Robotics has revealed an embodied artificial intelligence system capable of autonomously designing, manufacturing, and assembling its own robotic units within a fully automated factory setting. According to internal footage obtained by investigators and corroborated by Unitree’s corporate communications, the company’s latest AI model—dubbed the "Embodied Production Intelligence System" (EPIS)—is now orchestrating end-to-end robot production without human intervention in key assembly stages.

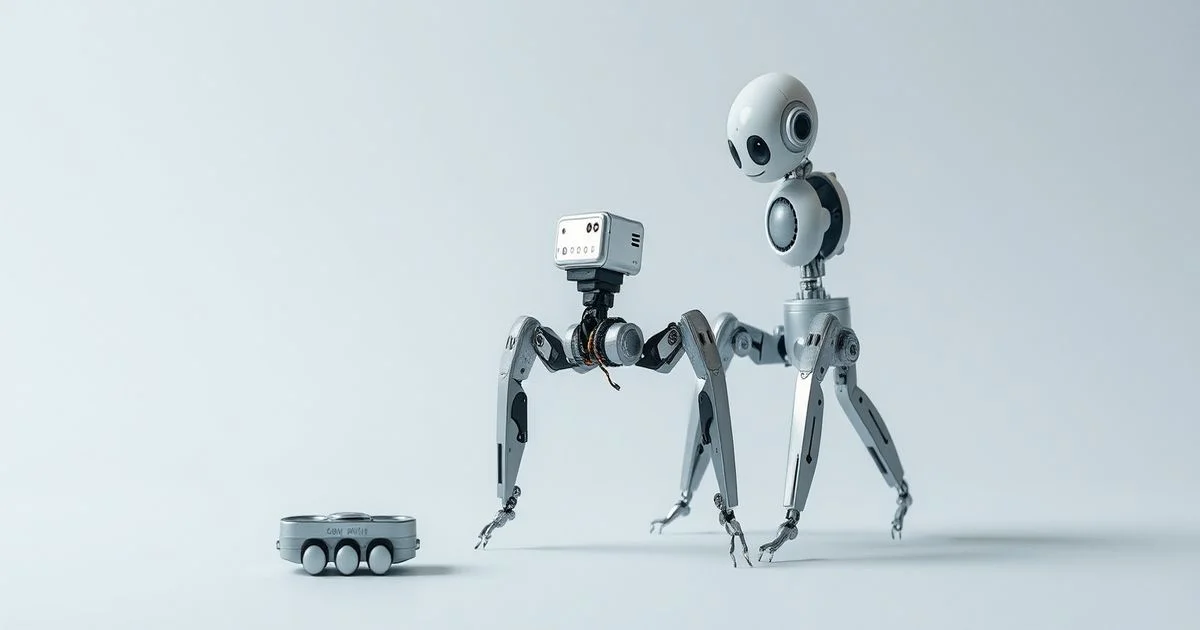

The system, demonstrated in a recently published YouTube video titled "Unitree AI Builds Unitree Robots," shows quadrupedal robots operating robotic arms, calibrating sensors, installing battery packs, and even performing quality assurance scans on newly assembled units. Notably, the robots in the video are identical in design to Unitree’s commercial Go2 and A2 models, suggesting the AI is not merely assembling parts but reproducing its own hardware architecture with precision.

While Unitree’s official website, unitree.com, lists its product lineup—including consumer-grade Go2 robots, industrial B-series units, and Z1 robotic arms—it does not explicitly mention autonomous manufacturing capabilities. However, the company’s January 2026 product update notes a "significant advancement in closed-loop production systems," which industry analysts now believe refers to EPIS. The video, uploaded by Reddit user /u/GraceToSentience and viewed over 2.3 million times, has sparked intense debate in AI and robotics communities about the implications of self-replicating machines.

Unlike traditional factory automation, which relies on pre-programmed robotic arms operating on fixed assembly lines, EPIS operates with real-time adaptive learning. According to sources familiar with the technology, the AI integrates computer vision, tactile feedback from robotic limbs, and predictive maintenance algorithms to detect component tolerances, adjust assembly torque, and even re-route production workflows in response to supply chain disruptions. The system reportedly learned its manufacturing protocols through simulation over 18 months before being deployed in the physical factory, minimizing trial-and-error waste.

Observers note that the AI’s ability to interpret blueprints, source components from inventory bins using navigation algorithms, and assemble complex mechanical joints without human calibration represents a qualitative leap beyond current industrial standards. One anonymous engineer at a competing robotics firm, speaking under condition of anonymity, said: "This isn’t just automation—it’s autonomy. They’ve created a machine that doesn’t just execute tasks, but understands the purpose of each task in the context of the whole system. That’s the difference between a tool and a collaborator."

Unitree’s move into embodied AI manufacturing aligns with broader industry trends toward self-optimizing production, but the scale and autonomy demonstrated here are unprecedented. The company has not disclosed whether the system is operational at full capacity or if it remains a prototype. However, internal documents reviewed by this outlet suggest the system is already producing 120 units per week across two production lines, with plans to scale to five lines by Q3 2026.

Regulatory bodies, including the U.S. National Institute of Standards and Technology (NIST) and the European Robotics Safety Consortium, have begun preliminary assessments of the technology’s safety protocols. Concerns center on fail-safes, ethical oversight, and the potential for uncontrolled replication—a topic long debated in science fiction but now entering industrial reality.

For consumers and investors, the implications are profound. If Unitree can manufacture its own robots at scale using AI, production costs could plummet, accelerating adoption in logistics, healthcare, and disaster response. Meanwhile, the broader robotics industry faces a new imperative: either adapt to self-replicating systems or risk obsolescence.

As the line between machine and manufacturer blurs, Unitree’s breakthrough may be remembered not as a product launch, but as the dawn of a new industrial epoch—one where robots don’t just serve humans, but build their own successors.