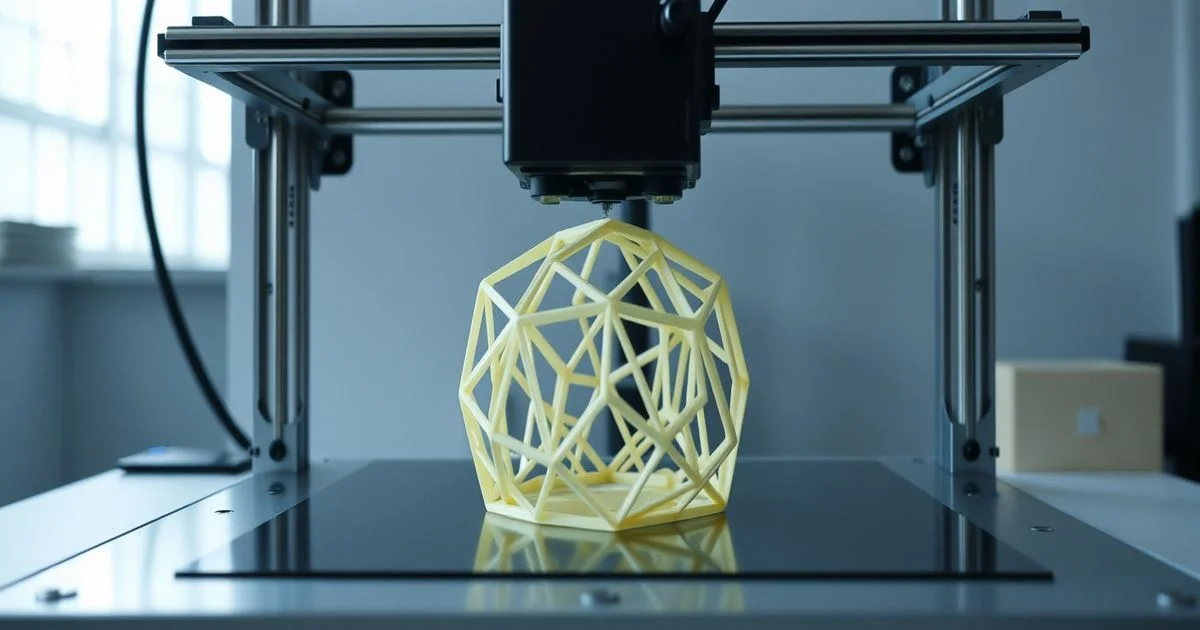

AI Controls 3D Printers in Real-Time: Revolutionizing Error Detection and Correction

Researchers have developed a modular system comprising five different AI agents to detect and correct manufacturing errors in 3D printers in real-time. The system is designed to work compatibly with various brands and models, aiming to enhance quality and reliability in additive manufacturing. This innovation signals a new era where artificial intelligence plays a critical role in production automation.

A New Era in AI-Assisted Manufacturing

While three-dimensional printing technology continues to revolutionize numerous fields from prototyping to mass production, one of the greatest challenges has been the real-time detection and correction of errors during the manufacturing process. Traditional methods have typically been limited to post-print inspections, leading to significant waste of time, materials, and energy. However, recent developments are providing a fundamental solution to this problem. Researchers have developed a system where five different artificial intelligence agents collaborate, creating a control mechanism that monitors the 3D printing process layer by layer and intervenes instantly.

Modular System and Multiple AI Agents

The system's most notable feature is its modular design and the synchronized operation of multiple AI agents. Each AI agent is specialized to monitor and analyze a different aspect of the printing process. While one agent controls temperature and material flow, another monitors layer alignment, and yet another oversees structural integrity in real-time. This collective work provides a level of monitoring and analysis that a single system could not encompass. Thanks to its developed open architecture, the system can operate compatibly with different brands and models of 3D printers, which greatly facilitates industrial adaptation.

How Does Real-Time Error Detection and Correction Work?

The system scans each print layer at a millimeter level through high-resolution sensors and cameras. The collected data is processed instantly by the AI agents. Algorithms trained on thousands of pre-learned successful and failed print data can detect the slightest anomaly—such as layer separation, void formation, or material irregularity—as it occurs. Following detection, the system not only issues an alert but also activates correction protocols. This involves dynamically adjusting print parameters like nozzle temperature, print speed, or material flow rate to compensate for the detected error, often before it compromises the structural integrity of the entire object. The system's ability to learn from each intervention continuously improves its predictive accuracy and corrective responses over time.

Implications for Industry 4.0 and Smart Factories

This advancement represents a significant leap toward fully autonomous smart factories envisioned in Industry 4.0. By integrating real-time AI control, manufacturers can achieve unprecedented levels of production consistency, reduce waste, and lower operational costs. The modular nature of the system means it can be deployed across existing production lines without requiring complete overhauls, making it a scalable solution for both small workshops and large industrial facilities. Experts predict that such intelligent systems will become standard in additive manufacturing within the next decade, fundamentally changing how products are designed, prototyped, and produced.

recommendRelated Articles

Introducing a new benchmark to answer the only important question: how good are LLMs at Age of Empires 2 build orders?

Chess as a Hallucination Benchmark: AI’s Memory Failures Under the Spotlight