Agentic AI Revolutionizes 3D Printing with Real-Time Error Correction

A groundbreaking AI system employing five specialized agents is set to transform 3D printing by monitoring and rectifying errors instantly after each layer is produced. This innovative approach promises to enhance print quality and reduce waste across various 3D printer models.

Agentic AI Revolutionizes 3D Printing with Real-Time Error Correction

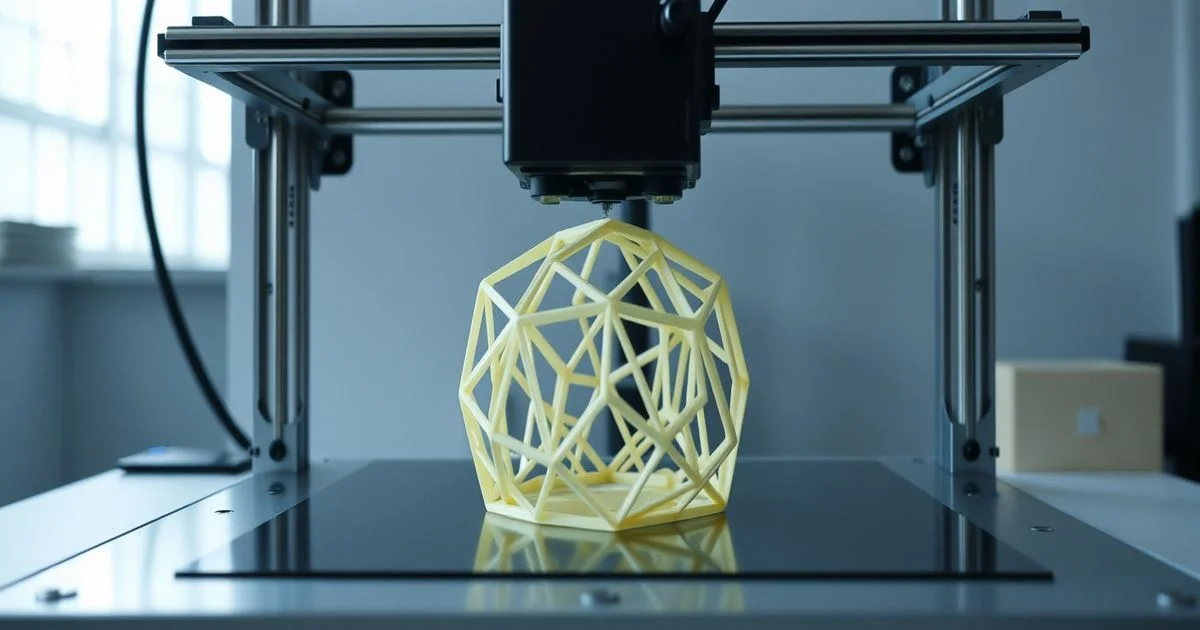

In a significant leap forward for additive manufacturing, a consortium of researchers has unveiled an advanced artificial intelligence system designed to meticulously monitor and correct errors in 3D printing processes as they happen. This novel approach, detailed in a recent report, utilizes a sophisticated network of five distinct AI agents working in concert to ensure the integrity and quality of 3D-printed objects from start to finish.

The core innovation lies in the system's ability to detect and address flaws immediately after each layer of material is deposited. Unlike traditional methods that often require manual inspection or result in wasted materials when errors are discovered late in the printing cycle, this agentic AI intervenes proactively. This real-time correction capability is poised to dramatically improve the success rate of complex prints, minimize material waste, and ultimately reduce production costs.

A Modular Approach to Universal Compatibility

A key feature of this intelligent monitoring system is its modular design, which grants it the flexibility to operate with a wide range of 3D printer makes and models. This interoperability is crucial for widespread adoption, as it negates the need for bespoke solutions for different hardware platforms. The researchers have engineered the system to be adaptable, allowing it to interface with various printer configurations and material types, thereby democratizing access to high-precision 3D printing.

The five AI agents are understood to perform specialized functions, though specific details of their individual roles remain under wraps pending further publication. However, it is theorized that these agents collectively handle tasks such as visual inspection of newly printed layers, analysis of deviations from the intended design, calculation of necessary adjustments, and the execution of those corrections on the printer's parameters. This distributed intelligence model allows for a robust and efficient error-handling pipeline.

Implications for Industry and Hobbyists Alike

The implications of this technology are far-reaching, impacting both industrial-scale manufacturing and the burgeoning hobbyist 3D printing community. For manufacturers, the ability to guarantee print quality and reduce the incidence of failed prints translates directly to increased productivity and lower overheads. Complex components for aerospace, medical devices, and automotive industries, where precision is paramount, could see a significant boost in reliability.

For enthusiasts and small businesses, this system offers a pathway to more consistent and professional-quality prints without the steep learning curve or the frustration of repeated failures. It could lower the barrier to entry for creating intricate prototypes, custom parts, and artistic creations, fostering greater innovation and creativity within the 3D printing ecosystem.

The Future of Self-Correcting Manufacturing

The development of agentic AI for 3D printing represents a significant step towards fully autonomous and self-correcting manufacturing processes. As AI continues to evolve, we can anticipate even more sophisticated systems that not only correct errors but also optimize print parameters on the fly for enhanced speed and material efficiency. This research highlights the transformative potential of artificial intelligence in reshaping traditional manufacturing paradigms.

While the initial report provides a compelling overview of the system's capabilities, the research team is expected to release further details on the specific algorithms and agent functionalities in the near future. The broader scientific and engineering communities will undoubtedly be watching closely as this technology matures and begins to find its place in the rapidly advancing world of 3D printing.